FEATURES

§ To meet the requirements from large and medium-sized enterprises We have developed enhanced shrinking and forming machineThis new model has longer length on Pre-heating area/ Steaming area/ Drying and forming area/Cooling and Collecting area respectively and have much more outstanding preshrinking effect.

§ Equipped with high-heat effect material which is over 30% energy-saving than other ordinary ones. Recycled internal heat system is saving much

power consumption as well. Feeding speed adjustable: customers can adjust the preshrinking speed based on different fabrics.

Wide application: Knitting fabric, woven cloth, denim and so on are applicable.

§ Easy operation: powerful cooling system and swinging folding device. The pre-humidity,steam volume and temperature all can be set and adjusted. After the fabrics being steamed and relaxed, the steam volume in different area is distributed in even and it will soften and form shape for the fabrics in the stable extent.

§ The fabrics are conveyed into the dry area through the vibration area so that the steamed fabrics can be dried quickly in the best temperature.

§ With powerful cooling system, the temperature of fabrics will be cool down promptly. The fabrics will be formed well due to the temperature

difference.

§ The Meter Counter, equipped as standard, can accurately measure the length of the fabric after forming.

§ It’s the latest energy saving and environmental protection model with the unique design,sealed working, no difference between temperature and humidity.

§ The steam operates and discharges in the convection-current mode so as to speed up the preheating effect and make the steam injection more uniform.

Opion;Production under customized demand is available.L:Pre-wet zone,drying zone,cooling zone lengthened;H:drying zone with heater;W:pre-wet zone,drying zone,cooling zone widened.

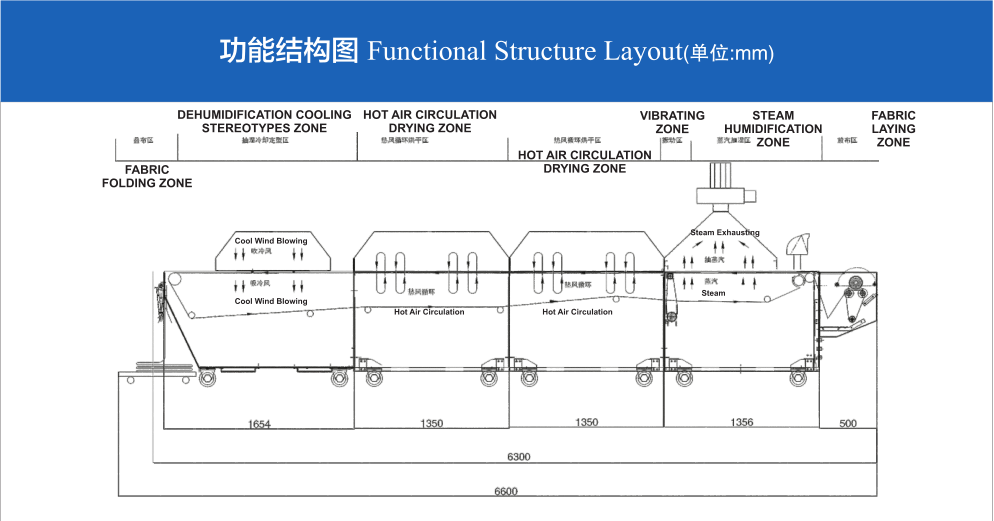

TF-3800L Functional Structure Layout

Specification

Model | TF-3800 | TF-3800L | TF-3800H | TF-3800LH | TF-3800W |

| Power supply | 3P220V-380V | ||||

| Air pressure | 0.5-0.7Mpa | ||||

| Steam consumption | 150kg/hr | 200kg/hr | 100kg/hr | 100kg/hr | 150kg/hr |

| Shrink width | 1850mm | ||||

| Total power | 3.59KW | 4.33KW | 24KW | 24KW | 3.59KW |

| Cooling motor | 0.75KW*4 | 0.75KW*5 | 0.75KW*4 | ||

| Main motor | 0.4KW | ||||

| Cloth stand motor | 90W | ||||

| Belt speed | 0-10m/min | ||||

| Machine size LxWxH | 3730X2600X1950mm | 6300X2600X1950mm | 3730X2600X1950mm | 6300X2600X1950mm | 3730X2900X1950mm |

| N.W / G.W | 1500/2000kgs | 2350/2850kgs | 1500/2000kgs | 2350/2850kgs | 1800/2300kgs |

Vedio