FEATURES

§ The machine uses the independent two-section compression. The silicon gel coated pressure roller cylinder compression method combined,which can make sure that the pressure is imposed stably and evenly on every point of the roller, ensuring the best fusing effect.

§ The independent two-section heating system is controlled by microprocessor temperature controller, making the temperature satisfactory.

§ The special monitor system can monitor the heating, the belt correction,the motor and the pressure, etc.. If there is an abnormality in operation,the machine can judge it automatically, which makes the maintenance easier and improves the productivity.

§ Auto timing rotating belt cleaning system can ensure the belt to run in the cleanest status, thus not affecting the surface of the cloths.

§ Powerful air-drawing cooling system can make the fused cloths relax and form so as to ensure the fusing effect.

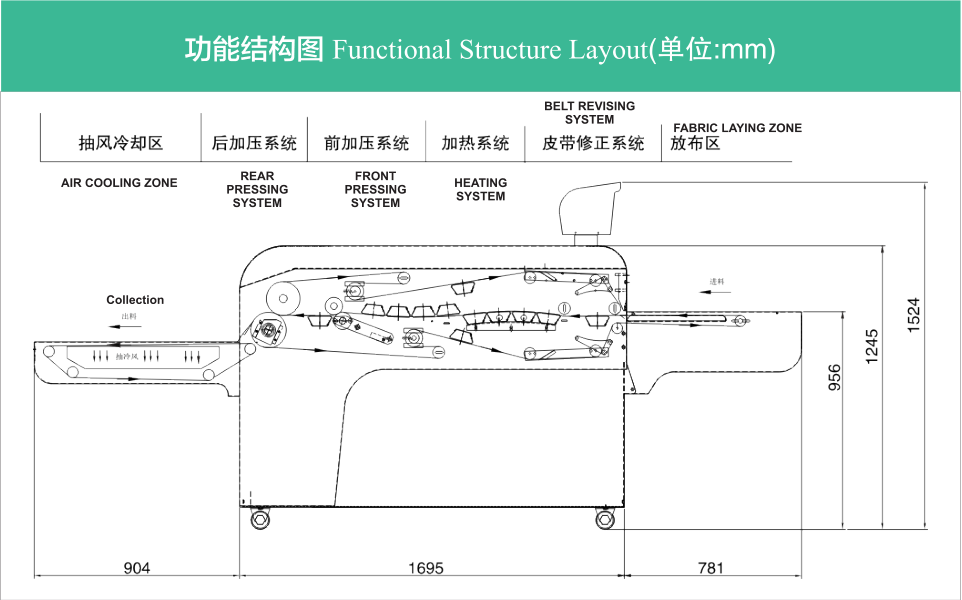

TF-600L/900L Functional Structure Layout

Specification

| Model | TF-600L | TF-900L |

| Power supply | 3P/380V | |

| Motor | 200 | 240 |

| Power | 13.2 | |

| Maximum pressure(kg/cm2) | 4 | |

| Set temperature | 常温-200℃ | |

| Fusing Width(mm) | 600 | 900 |

| Fusing Time(sec) | 10-34 | |

| Cloth scraper | 标准刮片 Standard Strip-off | |

| Machine size LxWxH(mm) | 3200x1210x1300mm | 3200x1540x1300mm |

| Packing size LxWxH(mm) | 2680x1350x1770mm | 2680x1670x1750mm |

| N.W / G.W | 730/830kgs | 830/930kgs |

Vedio